Water-Gate™ Self-inflating Barrier

The Water-Gate™ is a portable, self-inflating, reusable water barrier that can be used in place of traditional methods, such as sandbags, rock, or dirt dams. The Water-Gate™ can be installed or removed in minutes and easily packed and reused for a different application.

The portable barrier can be transported by vehicle to the required site or smaller barriers are light enough to be carried by a person. The Water-Gate™ can be installed by one person, with the barrier available in several lengths and heights and can be linked together to create longer sections.

Use of the Water-Gate™

The Water-Gate™ can be used in multiple situations like flood control, creating reservoirs and dams, waterway diversions and even chemical spill containment.

Water-Gate™ Barrier Categories

Water-Gate systems can be classified into 3 different categories: WL, WA and WT-Series.

WL Series

Used for flood and water control on asphalt, gravel and grass surfaces

Constructed from a high strength PVC fabric and is yellow in colour

Incorporates integrated ballasting system on the front barrier flap

Deployed either as a single barrier or as pre-joined sections

WA Series

Used for waterway diversion, temporary cofferdams or emergency water supply for firefighters

Made from high strength yellow PVC fabric

Lightweight and rapidly deployable.

Anti-mining flap at the rear of the barrier to reduce riverbed damage.

WT Series

Used for emergency interventions in hazmat/oil spills

Made from high strength yellow PVC fabric

Equipped with downstream release holes to create an underflow dam

Hydrocarbons/floating debris is collected in in front of the barrier

Clean water allowed to flow through the barrier via the flaps

Certification

Tested and certified by FM Global

We know how important it is for you or your organization to have the best anti flood system on the market. That’s why we have chosen to certify our products as FM Approved, by FM Global, one of the most widely accepted certifications in our industry.

The Water-Gate water barrier has undergone intensive testing to assess deployment speed, resilience, watertightness, and resistance to waves. Our FM Approved certification was performed in real time with all WL models exceeding 1m high have been tested and certified.

The tests were conducted in a test basin at the US Army Corps of Engineers in partnership with the Association of State Floodplain Managers (ASFPM), the US Army Corps of Engineers, and FM Global as part of a national testing and certification program for anti-flood products.

How does the Water-Gate™ Work?

Water-Gate barriers come as heavy-duty PVC roll. To use them, simply unroll them on the ground and let them do the work.

The water barrier will deploy by itself evenly and follow the height of the water level as it fluctuates.

The principle is simple: water enters and accumulates at the bottom of the barrier. As the water level rises, the barrier unfolds and swells.

An integrated floater, positioned directly at the top of the barrier, allows it to float at the rhythm of the waves, enabling it to reduce water overtopping the barrier. Once the barrier is deployed, it conforms to the ground and remains stable on most surfaces.

-

The water unfolds the barrier and flows inside it

-

As the water keeps flowing, the barrier starts to unfold and expand

-

The top of the barrier rides over the water waves as it continues to deploy

-

The Water-Gate™ barrier is fully deployed

By utilising this unique self-opening method, the Water-Gate™ reduces the time, effort and number of people needed to deploy the system, making this a truly rapid flood protection barrier.

The Water-Gate dam has four times more ground surface than the water being retained, thus four times more vertical thrust (over the ground) than the horizontal thrust for proper adhesion and added safety.

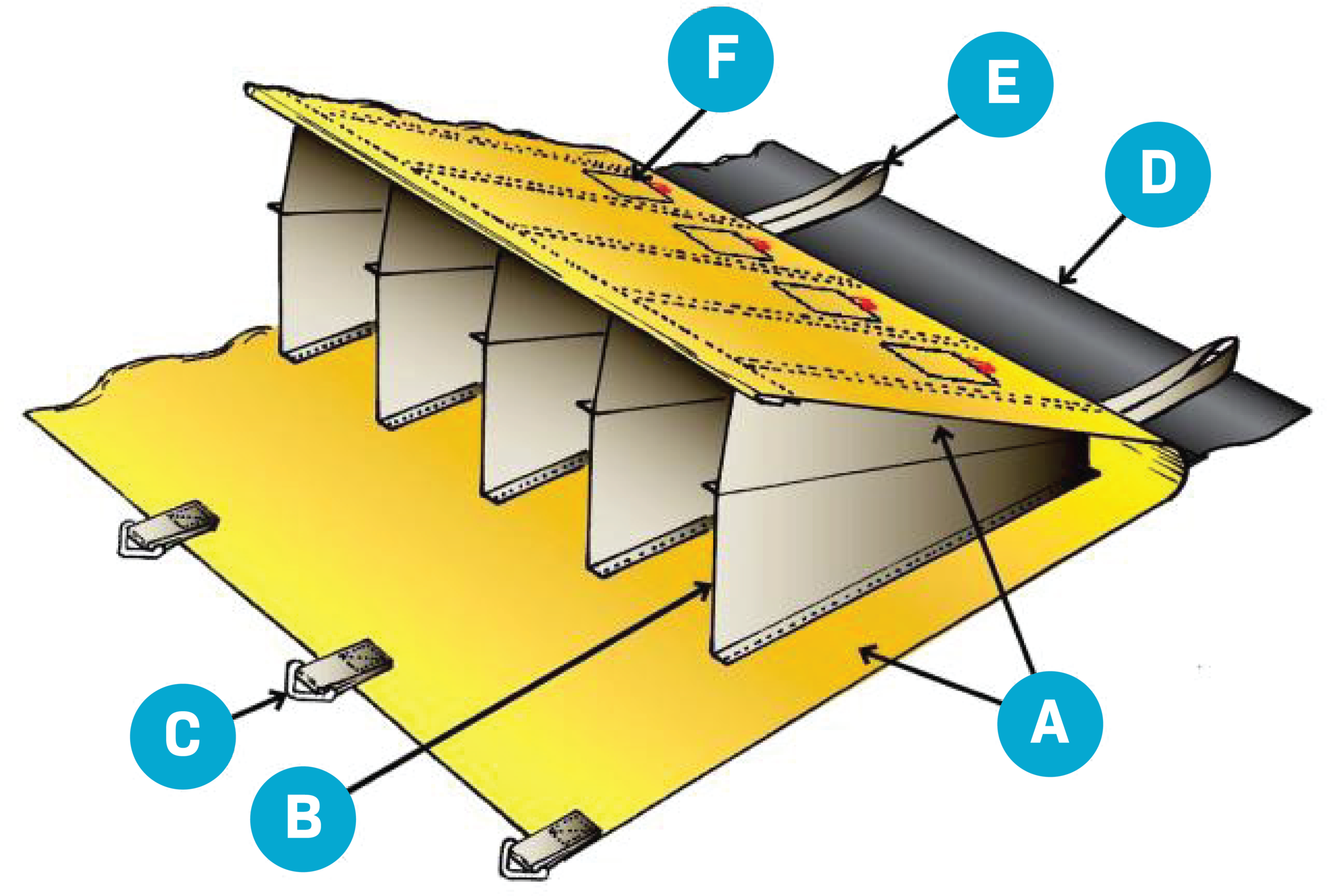

Parts of the Water-Gate™

Main characteristics of the Watergate barrier:

A – Polyester fabric coated with ultra-robust and abrasion resistant PVC for installations on all types of surfaces.

B – Stretched partitions providing better adherence on smooth surfaces.

C – Polypropylene straps to raise the barrier’s extremities for particular installations.

D – Overflow back flap or mining bib to prevent stream bed mining.

E – Resistant polypropylene straps for easy handling.

F – Release holes or ports with flaps and Velcro type sealing for underflow dam operations. With straps to pull the Velcro lined flaps open. Side attachment straps to control flow downward. (WT models)

Water-Gate™ Barrier Joins and Corners

Watergate barriers can be joined together using a simple Velcro flap method. It allows also different barrier sizes to be joined together as well.

Corners and Walls

The barrier can be folded to allow inside or outside corners as well as allowing wall attachments.

Water-Gate™ Accessories

-

Deployment crates

The crate enables covering long distances within a few minutes. This low-cost solution is simply the perfect tool for large deployment in a flash flood situation. Equipped with wheels that facilitate Water-Gate’s barriers transport and deployment, crates hold on average hold more than 100m of pre-joined Watergate barriers. These crates can be transported by a trailer, truck bed or directly set on a forklift.

-

Overflow Diverter Tunnel System

The Overflow Diverter Tunnel is installed on the Water-Gate™ allowing the overflow to be channelled downstream, allowing the draining of the bottom of the stream. This system replaces a heavy-duty pump and can drain 1200 imperial gal per minute or 90 litres per second. Abrasion resistant tunnels are installed onto the diverter to direct water to the required area.

-

Overflow Diverter

The overflow diverter tunnel is made from 100% polyethylene. The black portion of the diverter is funnel shaped to allow the draining of excess water. The (yellow) sliding float inside the diverter is used to stabilise the diverter when in use.

Weight: 14.5kg diverter only

Size: 380mm x 610mm x 1000mm -

Main Tunnel

The tunnel is used to channel the water downstream. It is fitted to the outlet of the diverter to direct the water where needed. It has red handles loops fitted every 1.5m for easier handling. The tunnel is 22.7 metres in length and made from abrasion resistant polyethylene canvas. Optional 22.7m extension tunnels can be fitted to cover the desired distance.

Tunnel Weight 11.4kg -

Ballasting Bags

Unrolls quickly to give uniform weight distribution along the front on the Water-Gate™ bib, to aid in the sealing of the barrier to the ground.

Weight 13.5 kg

Length 3m -

Pegs

Specially designed to hold the Watergate front bib in loose soil during the dewatering stage. The pegs have a corrosion-proof coating.

-

Lateral handles

Lateral handles are a convenient way to fix the edge of the barriers to anchor points when going up a wall or other supports, using multiple lateral handles on the barrier ends.

The Water-Gate™ water barrier can be deployed during very cold temperatures. It can resist to ice and to temperatures reaching -40°C. The water barrier can be installed on any surface and will curve to any given angle.

The Water-Gate™ barrier can be used in many situations ranging from flood control and blocking streams and waterways to creating water reservoirs and containing toxic spills (special model required for petrochemicals).

Flood Control

Several sections can be installed together quickly by a single person to create a flood protection barrier of the desired length. Alternatively, the WL model barrier can be deployed from a special crate containing over 100m of barrier in less than 2 minutes, giving protection up to 1.5m.

Blocking Streams and Waterways

The water barrier can be used to hold block streams and waterways without affecting the environment. This can be used to carry out culvert repairs or construction site dewatering projects

Creating Water Reservoirs

The Water-Gate™ barrier can be installed in streams to create water reservoirs to meet pumping needs especially with low waterway levels. This can be used by emergency services such as the Fire Service or Civil Defence to create a larger and deeper area to pump from. The barrier is lightweight, easy to deploy and remove.

Pollution Response - Release Hole Version

A modification to the Watergate barrier introduces a Velcro flap covering a series of holes. By removing the Velcro flap and exposing the holes, the cleaner water can flow through the barrier keeping the pollution containment behind the barrier for removal.

An alternative is a new below barrier diverter system, which works on the same principle of allowing the cleaner water to flow through the barrier, containing the pollutants.